So basically I just followed the steps of “Making Wooden Wheels with Drill Press” .

The reason for me to do that, is that I have experiences with otherMill and Router CNC, but actually have little experience with staffs just by simple tools. Especially little experience with drill press. I’m not sure if it can make things in a more simple and faster way.

The slight difference for my staffs is I changed the spade bits, since I couldn’t get staffs which is the same as the tutorials shows.

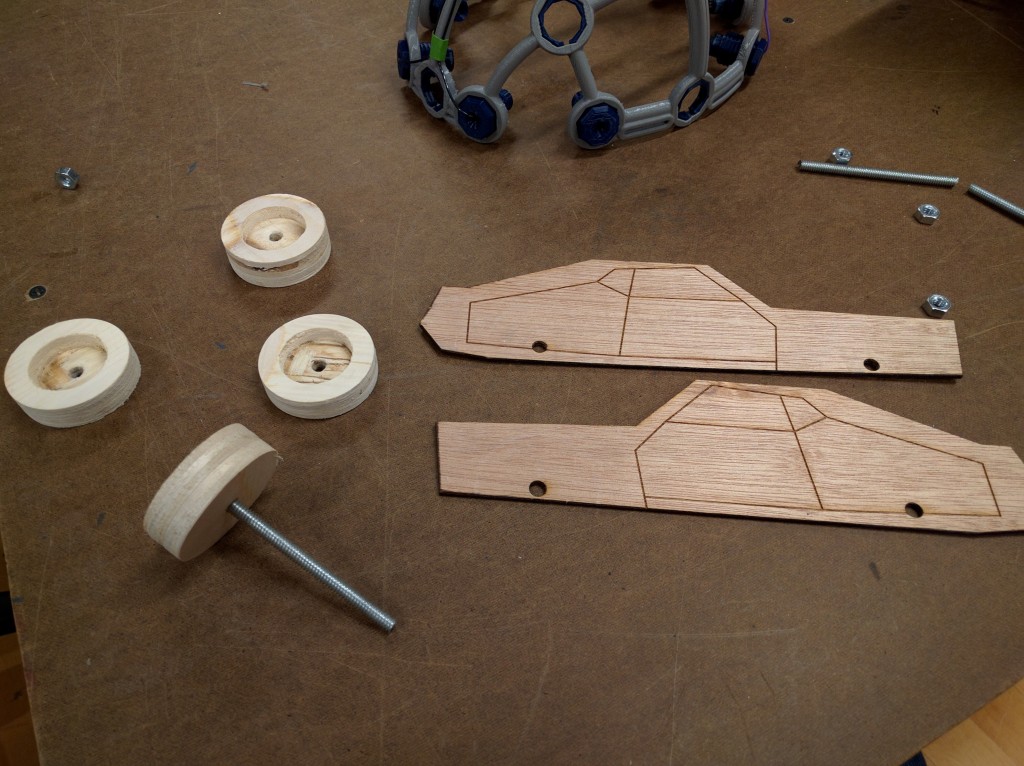

For the usage of the wheels, I decided to make the wheel to be a part of a musical car, which I will finish for the next few weeks.

During the fabrication, I found several points:

- It is very important to keep the materials to be horizontal. Other wise after drill, I can only get something with a quite strange shape

- It will be better to make the drill first, and then make spade, last drill everything out

- It is impossible to apply this logic with hand drill

- It is not worth to make wheels in such a logic — If you only need to make one or two simple wheels without the limitation of diameter and accuracy, then this logic is fine, but if you have requirement, CNC will be better choice. And frankly speaking, this logic is not fast if you are not familiar with that.

After I made four wheels, I decided to make a car, so I draw a picture and Laser cut it, and also make the axis just with some junk I found in ITP